Oil Suction Hose

Oil Suction Hose Specification

- Resistance level

- Resistant to oil, weather, mild chemicals

- Weight

- Varies depending on size, typically 3.2 kg/m 8.5 kg/m

- Temperature Resistance

- -40C to +70C

- Feature

- Flexible, abrasion-resistant and weather-proof

- Product Type

- Oil Suction Hose

- Width

- Varies depending on hose size, typically between 2 inches to 8 inches.

- Tolerance

- As per IS: 8189

- Style

- Smooth bore, corrugated or plain outer surface

- Density

- 1.3 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- Low thermal conductivity

- Natural Rubber

- Yes, compounded rubber blend

- Tensile Strength

- Minimum 10 MPa

- Hardness

- 605 Shore A

- Compression Ratio

- Up to 3:1 for temporary bending

- Color

- Black with identifying colored stripe

- Components

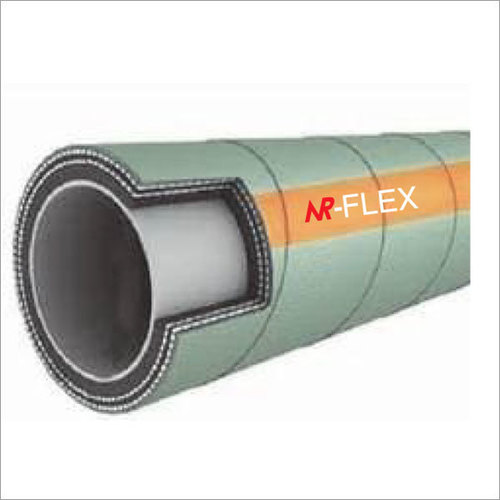

- Inner rubber lining, reinforcing plies of woven textile, embedded steel wire, external rubber cover

- Water Absorption

- Low water absorption

- Diameter

- 50 mm to 200 mm

- Rubber Type

- Natural/Synthetic Rubber blend

- Usage & Applications

- Used for suction and delivery of oil and petroleum products in industry, refineries, fuel stations, and oil rigs.

- Surface Finish

- Smooth or corrugated as per requirement

- Part Type

- Suction/Delivery Hose

- Flame Resistance Level

- Not flame resistant; protection required for high heat areas

- Length

- Standard length 7.5 m or 15 m; custom lengths available

- Size

- Standard sizes available from 50 mm to 200 mm (2 to 8).

- Material

- Natural & synthetic rubber with reinforcement

- Thickness

- 4 mm to 8 mm

- Ozone Resistance

- Yes, suitable for outdoor use

- Inner Tube

- Black, oil-resistant natural/synthetic rubber compound

- Working Pressure

- 10 bar (145 psi) higher ratings available

- Outer Cover

- Rubber compound resistant to abrasion, oil, ozone, and weathering

- End Connection

- Plain ends or fitted with flanged/quick-coupling ends as required

- Reinforcement

- Multiple layers of high tensile synthetic textile with embedded helical steel wire

- Electrical Conductivity

- Non-conductive or conductive as specified

- Compliance Standard

- IS: 8189 or equivalent international standards

- Minimum Bend Radius

- Specified as per hose diameter, typically 5x to 6x the hose bore

- Bursting Pressure

- At least 3 times the working pressure

Oil Suction Hose Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

About Oil Suction Hose

Oil Suction Hose

CONSTRUCTION:

- Tube: Rubber inner lining of nitrile/synthetic/ blend rubber compound, free from porosity, air blisters, or any other visible defects.

- Reinforcement: A reinforcement of one or more layers of nitrile/synthetic fibre or combination there of; applied by a suitable technique. Spiral wire (Galvanized Steel Wire).

- Cover: Abrasion resistant, outer rubber cover corrugated or smooth.

- Temperature Range: -40C up to+ 80C

APPLICATIONS: Oil suction is used for suction and delivery of oil, in dam projects.

END CONNECTIONS Each hose length has soft ends for clamping or can be supplied with built in nipple and flanges on request.

Specification

| Hose ID | Working pressure | Burst Pressure | |||

| Inch | mm | BAR | PSI | BAR | PSI |

| 11/2 | 38 | 10 | 145 | 30 | 435 |

| 2 | 50 | 10 | 145 | 30 | 435 |

| 21/2 | 62 | 10 | 145 | 30 | 435 |

| 3 | 75 | 10 | 145 | 30 | 435 |

| 31/2 | 90 | 10 | 145 | 30 | 435 |

| 4 | 100 | 10 | 145 | 30 | 435 |

| 5 | 125 | 10 | 145 | 30 | 435 |

| 6 | 150 | 10 | 145 | 30 | 435 |

| 8 | 200 | 10 | 145 | 30 | 435 |

| 10 | 250 | 10 | 145 | 30 | 435 |

| 12 | 300 | 10 | 145 | 30 | 435 |

Robust Construction for Demanding Applications

Built with multiple layers of high tensile synthetic textile along with embedded steel wire, this oil suction hose delivers outstanding strength and flexibility. Its smooth or corrugated outer surface, combined with abrasion-resistant, oil-resistant rubber compounds, ensures long-term reliability in tough industrial settings or outdoor environments.

Superior Oil and Weather Resistance

The inner tubes natural/synthetic rubber blend resists oil, while the outer cover shields against ozone, abrasion, and weathering. This design guarantees continued performance for the safe suction and delivery of oil and petroleum products across refineries, fuel stations, and oil rigs, even under challenging conditions.

Versatile Connections and Customization Options

Choose from various end connections including flanged or quick-coupling styles for maximum adaptability. With a wide selection of sizes and lengths, plus smooth or corrugated surface finishes, these hoses can be tailored to meet specific industrial or commercial requirements with ease.

FAQs of Oil Suction Hose:

Q: How is the Oil Suction Hose reinforced for durability?

A: The hose is reinforced with multiple layers of high tensile synthetic textile and an embedded helical steel wire, improving its flexibility and resistance to pressure fluctuations during suction and delivery operations.Q: What are the recommended application environments for this hose?

A: It is ideal for the suction and delivery of oil and petroleum products in industrial settings, refineries, fuel stations, oil rigs, and anywhere abrasion, oil, ozone, and weather resistance are required.Q: When should I use a hose with higher working pressure ratings?

A: Higher working pressure-rated hoses are recommended if your application involves pressures above the standard 10 bar (145 psi), such as in high-capacity industrial processes or where the conveyed fluids exert greater pressure.Q: Where can fittings and hose ends be customized?

A: End connections can be ordered plain or fitted with various options like flanged or quick-couplings, tailored to meet specific site requirements or compatibility with existing industrial equipment.Q: What benefits do the abrasion and ozone-resistant covers provide?

A: The outer cover protects the hose from wear due to friction, oil exposure, ozone, and weathering, extending the hoses service life and ensuring safe and efficient operations outdoors or in harsh environments.Q: How should the minimum bend radius be determined for installation?

A: The minimum bend radius depends on the hose diameter, typically 5 to 6 times the hose bore. Always consult the hose diameter specifications to prevent damage or kinking when installing.Q: What standards does this hose comply with?

A: It is manufactured according to IS: 8189 or equivalent international standards, ensuring optimal safety, reliability, and performance in industrial oil handling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Hose Category

Carbon Free Hose

Minimum Order Quantity : 50 Meters

Diameter : 12 mm to 100 mm (inner diameter)

Rubber Type : Synthetic/Carbonfree compounded rubber

Usage & Applications : Used for transferring electrical cables, hydraulic fluids and cooling in furnace and foundry operations; ideal for environments requiring nonconductive hoses

Surface Finish : Smooth, durable outer layer

Part Type : Hose/Pipe

Wire Braid Hydraulic Hose

Minimum Order Quantity : 50 Meters

Diameter : 6 mm to 50 mm (inner diameter options)

Rubber Type : Nitrile (NBR)/SBR/CR synthetic rubber

Usage & Applications : Hydraulic systems, industrial machinery, construction equipment

Surface Finish : Smooth or wrapped (customizable)

Part Type : Hydraulic Hose

Wire Braid Hydraulic Hose

Minimum Order Quantity : 50 Meters

Diameter : 1/4 inch to 2 inch

Rubber Type : Nitrile Butadiene Rubber (NBR)/Synthetic Rubber

Usage & Applications : High pressure hydraulic systems, industrial and construction machinery, earthmoving equipment, mining machines, hydraulic oil delivery

Surface Finish : Smooth or wrapped

Part Type : Hydraulic Hose

SAE 100 R3 / EN854

Minimum Order Quantity : 1000

Diameter : ID: 4.8mm to 50.8mm, OD varies by size

Rubber Type : NBR/SBR synthetic blend

Usage & Applications : Hydraulic and low pressure industrial applications, petroleum or water based fluids conveyance

Surface Finish : Smooth or fabric impression finish

Part Type : Industrial Hose

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry