SAE 100 R3 / EN854

SAE 100 R3 / EN854 Specification

- Part Type

- Industrial Hose

- Length

- Standard: 50-100 meters per roll (other lengths on request)

- Thickness

- As per EN854 (varies with size)

- Color

- Black with colored identification stripes

- Weight

- Varies by size and length

- Usage & Applications

- Hydraulic and low pressure industrial applications, petroleum or water based fluids conveyance

- Diameter

- ID: 4.8mm to 50.8mm, OD varies by size

- Material

- Inner tube: NBR synthetic rubber; Reinforcement: Two textile braids; Outer cover: SBR/NBR synthetic rubber

- Product Type

- Hydraulic Hose

- Hardness

- Shore A 75 5

- Style

- Double fiber braid reinforced, non-metallic

- Temperature Resistance

- -40C to +100C (intermittent up to +120C)

- Width

- Defined by hose size (see below)

- Surface Finish

- Smooth or fabric impression finish

- Flame Resistance Level

- Limited (not flame-retardant unless specified)

- Water Absorption

- Low

- Size

- 3/16 to 2 (4.8mm to 50.8mm)

- Resistance level

- Excellent oil, abrasion, and weather resistance

- Components

- Inner tube, double braid fiber reinforcement, outer cover

- Tolerance

- ISO 1307, EN 854 standard tolerances

- Density

- 1.4 Gram per cubic centimeter(g/cm3)

- Natural Rubber

- Blend of synthetic rubber (NBR) and natural rubber

- Feature

- Flexible, abrasion and oil resistant, lightweight, easy to install

- Rubber Type

- NBR/SBR synthetic blend

- Tensile Strength

- Varies by size, typically 15 MPa (inner tube)

- Marking

- Continuous ink jet printing as per standard or customer request

- Reinforcement

- Two high tensile synthetic textile braids

- Conformance

- Complies with SAE J517, EN854 type R3

- Minimum Bend Radius

- Varies by size (see manufacturers chart)

- Working Pressure

- Up to 40 bar (580 psi) depending on size

- Quality Control

- 100% tested for pressure and leakage

- Outer Cover

- Abrasion, weather, and oil-resistant synthetic rubber (SBR/NBR)

- Burst Pressure

- Minimum 4x working pressure

- Standard

- SAE 100 R3 / EN854

- Packaging

- Wrapped in roll, standard export packing

- Inner Tube

- Oil-resistant synthetic rubber (NBR)

- Electrical Resistance

- Non-conductive, on request

SAE 100 R3 / EN854 Trade Information

- Minimum Order Quantity

- 1000 Meter

- Supply Ability

- Meter

- Delivery Time

- 1 Week

About SAE 100 R3 / EN854

Wire Braid Hydraulic Hose

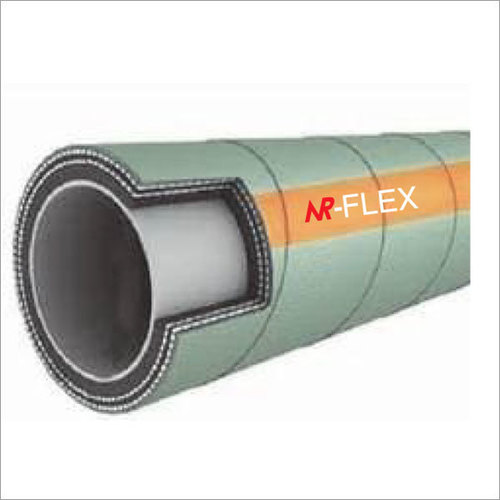

CONSTRUCTION:

- Tube: Oil Resistant synthetic rubber.

- Reinforcement: Two textile braids wire braid.

- Cover: Abrasion, Ozone & weather resistant synthetic rubber.

- Temperature Range : Medium From -40C up to+100C

APPLICATIONS: Hose range suitable to carry hydraulic fluids such as glycol, mineral oils fuels, lubrication, emulsion, hydrocarbons etc.

Specification

| Hose ID | Wire OD | Hose OD | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | |||

| Inch | mm | mm | mm | BAR | Psi | BAR | Psi | mm | Kg/m |

| 5 | 3/16 | 4.8 | 12.7 | 105 | 1520 | 420 | 6500 | 75 | 0.16 |

| 6 | 1/4 | 6.4 | 14.3 | 87 | 1350 | 348 | 5300 | 75 | 0.19 |

| 8 | 5/16 | 7.9 | 17.5 | 84 | 1300 | 336 | 5200 | 100 | 0.26 |

| 10 | 3/8 | 9.5 | 19.0 | 78 | 1200 | 312 | 4840 | 100 | 0.28 |

| 13 | 1/2 | 12.7 | 23.8 | 70 | 1080 | 280 | 4340 | 125 | 0.40 |

| 16 | 5/8 | 15.9 | 27.0 | 61 | 945 | 244 | 3780 | 140 | 0.55 |

| 19 | 3/4 | 19.0 | 31.8 | 52 | 800 | 205 | 3220 | 150 | 0.69 |

| 25 | 1 | 25.4 | 38.0 | 39 | 600 | 155 | 2420 | 205 | 0.82 |

| 32 | 1-1/4 | 31.8 | 44.4 | 26 | 400 | 104 | 1610 | 250 | 1.00 |

Superior Construction and Durability

This hose combines a blend of synthetic NBR and SBR rubber for both the inner tube and outer cover, ensuring premium oil, abrasion, and weather resistance. The double fiber braid reinforcement delivers enhanced tensile strength and flexibility, making installation and maneuvering straightforward for users in demanding conditions.

Versatile Applications

Suitable for hydraulic, industrial, and low-pressure fluid transportation, this hose is utilized in various sectors including manufacturing, agriculture, and construction. It reliably handles petroleum or water-based fluids, maintaining performance even in variable temperatures from -40C to +100C.

Quality and Compliance Assured

Each hose is rigorously pressure and leakage tested and wrapped in rolls for export. It complies with SAE J517 and EN854 R3 standards, following ISO tolerances and customer-specific marking, ensuring consistency and safety for distributors and end-users alike.

FAQs of SAE 100 R3 / EN854:

Q: How is the SAE 100 R3 / EN854 hose tested for quality assurance?

A: Every hose undergoes 100% pressure and leakage testing to ensure reliability, compliance with SAE J517 and EN854 standards, and optimal performance in prescribed working conditions.Q: What applications are ideal for using SAE 100 R3 / EN854 hoses?

A: These hoses are designed for hydraulic and low-pressure industrial applications, such as conveying petroleum-based or water-based fluids in manufacturing, agriculture, or construction environments.Q: When should I opt for the non-conductive version of this hose?

A: Select the non-conductive variant when electrical insulation is required, ensuring safer operations in environments prone to static electricity or electrical exposure.Q: Where can the SAE 100 R3 / EN854 hose be installed?

A: It can be installed wherever flexible, lightweight, and oil-resistant hose solutions are necessaryindoors or outdoorsthanks to its abrasion and weather-resistant outer cover.Q: What is the main benefit of the double fiber braid reinforcement?

A: This reinforcement significantly enhances hose flexibility, strength, and ease of installation, ensuring long service life and resistance to kinking or pressure surges.Q: How does the hose handle harsh weather and chemicals?

A: The robust SBR/NBR synthetic rubber blend offers excellent resistance against oil, abrasion, weather, and chemicals, maintaining hose integrity even under challenging conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Hose Category

Rubber Hose for Conveying Concrete

Minimum Order Quantity : 50 Meters

Tensile Strength : 12~20 MPa

Rubber Type : Natural/SBR Blend

Feature : Abrasion Resistant, Flexible, High Impact Resistance

Natural Rubber : High quality natural and synthetic rubber blend

Density : 1.25 Gram per cubic centimeter(g/cm3)

Carbon Free Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : 120130 kg/cm (average)

Rubber Type : Synthetic/Carbonfree compounded rubber

Feature : Heat resistant, nonconductive, abrasion resistant, long life

Natural Rubber : Yes, reinforced with synthetic fabric/steel wire

Density : 1.5 Gram per cubic centimeter(g/cm3)

Fly Ash Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : Above 10 MPa

Rubber Type : Blend of synthetic/natural rubber

Feature : Highly abrasion resistant, reinforced construction, kink resistant

Natural Rubber : Available on request (special grade blend)

Density : 1.5 Gram per cubic centimeter(g/cm3)

Water Rubber Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : 1018 MPa

Rubber Type : Natural Rubber blended with synthetic

Feature : Durable, Leakproof, Smooth finish

Natural Rubber : Yes, blended with synthetic rubber

Density : 1.5 Gram per cubic centimeter(g/cm3)

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry