Fly Ash Hose

Fly Ash Hose Specification

- Natural Rubber

- Available on request (special grade blend)

- Components

- Inner tube, reinforcement, external cover

- Rubber Type

- Blend of synthetic/natural rubber

- Tolerance

- As per IS standards

- Surface Finish

- Textured/corrugated outer, smooth inner

- Thickness

- 6 mm to 12 mm

- Density

- 1.5 Gram per cubic centimeter(g/cm3)

- Color

- Black

- Length

- Standard 6 m; available up to 20 m

- Weight

- Variable as per size and length

- Water Absorption

- Negligible

- Hardness

- 60 5 Shore A

- Material

- Rubber (synthetic or natural), fabric, wire helix

- Tensile Strength

- Above 10 MPa

- Style

- Smooth bore, corrugated outer cover

- Width

- Customizable

- Resistance level

- High resistance to abrasion and wear

- Diameter

- 50 mm to 300 mm (custom options available)

- Thermal Conductivity

- Low

- Temperature Resistance

- -30C to +85C

- Part Type

- Hose assembly

- Flame Resistance Level

- Flame retardant (optional grade available)

- Product Type

- Flexible Fly Ash Hose

- Usage & Applications

- Fly ash handling, bulk material transfer, cement plants, pneumatic conveying systems

- Size

- 2 to 12 (varies as per requirement)

- Compression Ratio

- 3:1

- Feature

- Highly abrasion resistant, reinforced construction, kink resistant

- Burst Pressure

- Up to 30 bar (varies by size)

- End Fittings

- Flanged, plain, or as required

- Service Life

- Up to 5 years under recommended usage

- Conformance

- IS 1307, ISO 4639 guidelines

- Working Pressure

- 10-20 bar, depending on diameter

- Electrical Resistance

- Antistatic properties on request

- Reinforcement Material

- Textile plies with embedded steel wire helix

- Packaging

- Coil or straight length

- Environment Compatibility

- Ozone and weather resistant

- Minimum Bending Radius

- 5 × internal diameter

Fly Ash Hose Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

About Fly Ash Hose

Fly Ash Hose

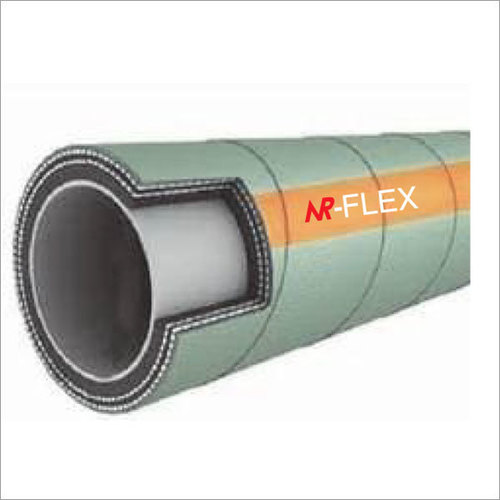

CONSTRUCTION:

- Tube: Natural/SBR Rubber compound having very high resistance to abrasion

- Reinforcement: Natural & Synthetic fabrics/GI wire

- Cover: Modified natural rubber having high resistance to weather & abrasion

- Temperature Range : Medium From -10°C up to+100°C .

- End Connection : Each length have soft ends or built in flanges fitted at the ends

APPLICATIONS:Dry Fly Ash Hose is widely used in Cement Plants for discharge of Ash. Hoses are fabricated with high tensile Nylon Fabric for heavy duty application. We offer customized Fly Ash discharge hoses in various sizes & length.

Specification

| Hose ID | Type 1 | Type ll | |||

| Inch | mm | Working pressure (BAR) | Burst Pressure (BAR) | Working pressure (BAR) | Burst Pressure (BAR) |

| 2 | 50 | 10 | 40 | 15 | 60 |

| 3 | 75 | 10 | 40 | 15 | 60 |

| 4 | 100 | 10 | 40 | 15 | 60 |

| 5 | 125 | 10 | 40 | 15 | 60 |

| 6 | 150 | 10 | 40 | 15 | 60 |

| 8 | 200 | 10 | 40 | 15 | 60 |

Highly Durable Design

Engineered for longevity, the hose is built with textile plies and an embedded steel wire helix, providing robust reinforcement against physical stresses. Its abrasion-resistant exterior and kink-resistant architecture make it suitable for continuous operation in harsh industrial environments, minimizing downtime and replacement needs.

Customizable and Versatile Application

With customizable widths, diameters, lengths, and end fittings, this hose adapts to varied requirements across cement plants, fly ash handling, and bulk material transfer systems. The smooth bore and corrugated outer cover ensure optimal flow while accommodating specific setup needs for pneumatic conveying and other industrial uses.

Safety and Compliance Assurance

The hose conforms to IS 1307 and ISO 4639 standards, ensuring top-tier safety, reliability, and quality. Optional antistatic and flame retardant features cater to environments where static discharge or fire risk is a concern. Ozone and weather resistance further enhance its suitability for outdoor or aggressive conditions.

FAQs of Fly Ash Hose:

Q: How does the Fly Ash Hose ensure safe transportation of abrasive bulk materials?

A: The hose incorporates a reinforced construction with textile plies and a steel wire helix, combined with highly abrasion-resistant rubber blends. This ensures safe transfer of fly ash and bulk materials while minimizing wear, preventing premature failure, and providing kink resistance during operation.Q: What is the recommended process for selecting the correct hose size and end fittings?

A: Select hose size and fittings based on diameter requirements (50 mm to 300 mm), pressure needs (10-20 bar working), and application criteria. Consult with the distributor or manufacturer to specify flanged, plain, or custom end fittings, ensuring compatibility with existing systems and process flows.Q: When should the hose be replaced to maintain optimal performance?

A: Under recommended usage and compliant with IS guidelines, the hose offers a service life of up to five years. Regular inspections for wear, pressure capacity, and bend radius should be performed, and replacement is advised if significant abrasion, loss of flexibility, or signs of degradation appear.Q: Where is the Fly Ash Hose commonly used?

A: This hose finds application in cement plants, fly ash handling facilities, pneumatic conveying systems, and bulk material transfer operations. Its weather and ozone-resistant properties make it suitable for both indoor and outdoor industrial environments across India and international markets.Q: How do antistatic and flame-retardant properties benefit industrial operations?

A: Antistatic and flame-retardant options help reduce the risk of static discharge and fire hazards in high-dust or electrically charged settings. These features contribute to safer working conditions, particularly in plants handling fine particulate matter and flammable materials.Q: What are the advantages of the hoses low water absorption and thermal conductivity?

A: Low water absorption prevents degradation and swelling, maintaining dimension stability, while low thermal conductivity ensures that the hose remains structurally sound when exposed to temperature variations. This leads to reliable performance, longer service life, and reduced maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Hose Category

Carbon Free Hose

Minimum Order Quantity : 50 Meters

Components : Inner tube, reinforcement layer, outer cover

Natural Rubber : Yes, reinforced with synthetic fabric/steel wire

Rubber Type : Synthetic/Carbonfree compounded rubber

Surface Finish : Smooth, durable outer layer

Tolerance : 0.5 mm

Rubber Air Hose

Minimum Order Quantity : 50 Meters

Components : Rubber hose with textile/nylon wire reinforcement

Natural Rubber : Yes, high grade rubber compound

Rubber Type : NR/SBR blend

Surface Finish : Smooth, matte

Tolerance : +/ 1 mm

Sand Blast Rubber Hose

Minimum Order Quantity : 50 Meters

Components : Inner tube, reinforcement (fabric/wire), outer cover

Natural Rubber : Special abrasionresistant natural or synthetic rubber lining

Rubber Type : Blended with natural and synthetic rubbers for optimum performance

Surface Finish : Smooth or clothmarked/corrugated as per requirement

Tolerance : Standard tolerance, custom available upon request

Water Rubber Hose

Minimum Order Quantity : 50 Meters

Components : Rubber tube, reinforced layer, cover

Natural Rubber : Yes, blended with synthetic rubber

Rubber Type : Natural Rubber blended with synthetic

Surface Finish : Smooth

Tolerance : 0.5 mm

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry