Carbon Free Hose

Carbon Free Hose Specification

- Surface Finish

- Smooth, durable outer layer

- Diameter

- 12 mm to 100 mm (inner diameter)

- Flame Resistance Level

- Meets standard flame test requirements

- Components

- Inner tube, reinforcement layer, outer cover

- Material

- Non-conductive rubber compound (carbon-free), reinforced with synthetic fibers/steel wire

- Rubber Type

- Synthetic/Carbon-free compounded rubber

- Natural Rubber

- Yes, reinforced with synthetic fabric/steel wire

- Weight

- Depends on size and length (e.g., approx. 1.5 8 kg/m)

- Style

- Wire Braided and Fabric Braided

- Density

- 1.5 Gram per cubic centimeter(g/cm3)

- Ash %

- Negligible, as carbon content is minimal

- Feature

- Heat resistant, non-conductive, abrasion resistant, long life

- Size

- Available from 12 mm to 100 mm inner diameter

- Volatile Matter (%)

- < 2%

- Color

- Green/Orange/Red (other colors available on request)

- Length

- Standard 15 m, 30 m lengths (custom lengths available)

- Part Type

- Hose/Pipe

- Hardness

- 70 5 Shore A

- Usage & Applications

- Used for transferring electrical cables, hydraulic fluids and cooling in furnace and foundry operations; ideal for environments requiring non-conductive hoses

- Thermal Conductivity

- Low designed for insulation

- Temperature Resistance

- -40C to +180C

- Thickness

- 3 mm to 10 mm (varies by model)

- Width

- As per requirement (standard widths available)

- Tensile Strength

- 120130 kg/cm (average)

- Product Type

- Carbon Free Hose

- Tolerance

- 0.5 mm

- Water Absorption

- Negligible

- Resistance level

- High resistance to electricity, heat, chemicals

- Cover Type

- Weather and abrasion resistant synthetic rubber

- End Connection Options

- Flange, threaded, quick connect couplings

- Packaging Type

- Rolls, coils, or cut lengths

- Ozone Resistance

- Excellent

- Oil Resistance

- Yes, suitable for hydraulic fluids

- Reinforcement Type

- Synthetic fabric or steel wire braiding

- Storage Conditions

- Store in a cool, dry place away from direct sunlight

- Electrical Resistance

- > 1 Mega Ohm (non-conductive)

- Manufacturing Standard

- IS: 447 1988, IEC standards

- Bursting Pressure

- Up to 60 kg/cm

- Compliance

- RoHS and REACH compliant

- Minimum Bend Radius

- 5 times the inner diameter

- Life Expectancy

- Up to 5 years under standard operating conditions

Carbon Free Hose Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

About Carbon Free Hose

Carbon Free Hose

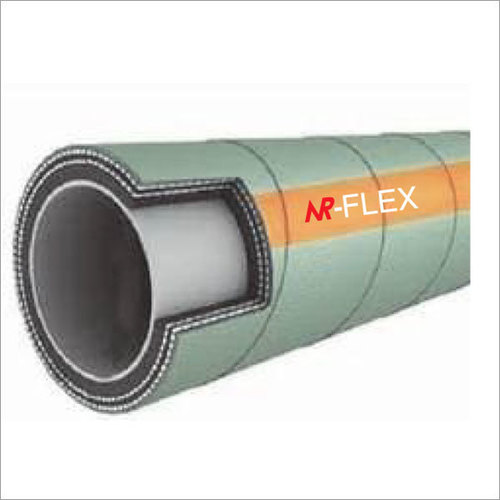

CONSTRUCTION:

- Tube: Modified Synthetic Rubber

- Reinforcement: High Tenacity Synthetic Yarn

- Cover: Modified Synthetic Rubber

- Temperature Range: -40C up to+100C

APPLICATIONS: Recommended for specialised furnace coolant applications.Engineered with specially developed carbon-free tube and cover, whereby meeting service requirements of low leakage current (Less than 20 micro amp at6KV DC).

Specification

| Hose ID | Hose OD | Working pressure | Burst Pressure | |||

| Inch | mm |

| BAR | PSI | BAR | PSI |

| 1/2 | 12 | 21.50 | 14 | 203 | 42 | 609 |

| 3/4 | 20 | 32.00 | 14 | 203 | 42 | 609 |

| 1 | 25 | 38.00 | 14 | 203 | 42 | 609 |

| 11/4 | 32 | 48.00 | 14 | 203 | 42 | 609 |

| 11/2 | 38 | 54.00 | 14 | 203 | 42 | 609 |

| 2 | 50 | 66.00 | 14 | 203 | 42 | 609 |

| 21/4 | 56 | 73.00 | 12 | 174 | 36 | 522 |

| 21/2 | 63 | 85.00 | 12 | 174 | 36 | 522 |

| 3 | 75 | 100.00 | 12 | 174 | 36 | 522 |

| 4 | 100 | 126.00 | 12 | 174 | 36 | 522 |

Reliable Non-Conductive Hose for Enhanced Safety

Our carbon-free hose surpasses electrical resistance requirements, ensuring safety in environments where conductivity could cause operational risks. The non-conductive rubber compound is reinforced with synthetic fabric or steel wire braiding to maintain strength and flexibility while delivering outstanding protection against electrical hazards. This makes it perfectly suited for transferring hydraulic fluids or electrical cables in industrial applications like foundries and furnaces.

Robust Construction for Harsh Conditions

Designed to withstand extreme temperatures (-40C to +180C), abrasive environments, and chemical exposure, the hose features a weather-resistant synthetic rubber cover. Excellent oil and ozone resistance provide long-lasting performance, whether used indoors or outdoors. Low water absorption and thermal conductivity further enhance the hoses insulating capabilities, making it ideal for intensive industrial and hydraulic systems.

Versatile Design and Customization Options

Available in standard and custom sizes (12 mm to 100 mm inner diameter), lengths (15 m, 30 m, or as required), and colors, the hose adapts to specific operational requirements. Multiple end connection stylesincluding flange, threaded, and quick connect couplingsensure easy integration with various systems. Roll, coil, or cut-length packaging options simplify transport and storage. RoHS and REACH compliance and adherence to IS: 4471988 and IEC standards guarantee safety and regulatory peace of mind.

FAQs of Carbon Free Hose:

Q: How does the Carbon Free Hose ensure electrical safety in industrial environments?

A: The hose is manufactured from a non-conductive rubber compound with electrical resistance exceeding 1 Mega Ohm, effectively preventing electrical transmission. This property is crucial for applications where the transfer of hydraulic fluids, electrical cables, or cooling in furnaces could pose hazards due to conductivity.Q: What processes are involved in manufacturing this hose to meet quality standards?

A: Production adheres strictly to IS: 4471988 and IEC standards, using carbon-free synthetic rubber compounded with either synthetic fabric or steel wire reinforcement. Each hose undergoes rigorous testing for burst pressure, electrical resistance, and other critical specifications to ensure compliance and safety.Q: When should the Carbon Free Hose be replaced for optimum performance?

A: Under standard operating conditions, the hose has a life expectancy of up to five years. It should be inspected regularly for wear, damage, or loss of flexibility. Replacement is recommended when visual signs of abrasion, cracks, or compromised electrical resistance are detected.Q: Where can this hose be most effectively utilized?

A: It is designed for use in foundries, furnace cooling systems, hydraulic fluid transfer, and electrical cable carrying applications, especially where non-conductive hoses are required to ensure operational safety and efficiency.Q: What are the key benefits of using this hose over conventional hoses?

A: Key advantages include its non-conductive nature, superior resistance to heat, oil, chemicals, and ozone, excellent durability, and regulatory compliance (RoHS, REACH). The hoses reinforced construction provides reliability in high-pressure systems, while the weather-resistant synthetic rubber cover extends service life.Q: How should the Carbon Free Hose be stored for maximum longevity?

A: To preserve its properties, the hose should be stored in a cool, dry environment, away from direct sunlight or sources of extreme heat. Suitable packaging includes rolls, coils, or custom cut lengths, helping to prevent deformation or degradation during storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Hose Category

Rubber Hose for Conveying Concrete

Minimum Order Quantity : 50 Meters

Resistance level : Resistant to Abrasion, Weathering, and Chemicals

Water Absorption : Negligible

Tolerance : 1 mm

Product Type : Rubber Hose for Conveying Concrete

Tensile Strength : 12~20 MPa

Fly Ash Hose

Minimum Order Quantity : 50 Meters

Resistance level : High resistance to abrasion and wear

Water Absorption : Negligible

Tolerance : As per IS standards

Product Type : Flexible Fly Ash Hose

Tensile Strength : Above 10 MPa

Sand Blast Rubber Hose

Minimum Order Quantity : 50 Meters

Resistance level : Excellent abrasion and weather resistance

Water Absorption : Negligible

Tolerance : Standard tolerance, custom available upon request

Product Type : Sand Blast Rubber Hose

Tensile Strength : Minimum 8 MPa or as per IS: 5894/90 standard

Air & Water Suction Hose

Minimum Order Quantity : 50 Meters

Resistance level : High resistance to weather, ozone, and abrasion

Water Absorption : Minimal

Tolerance : As per IS:3549/ISO standards

Product Type : Air & Water Suction Hose

Tensile Strength : 1216 MPa

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry