Wire Braid Hydraulic Hose

Wire Braid Hydraulic Hose Specification

- Style

- Braided

- Tensile Strength

- 180-420 MPa (Depending on size and model)

- Size

- 1/4 inch to 2 inches

- Flame Resistance Level

- Meets ISO 8030 standard

- Rubber Type

- Synthetic Rubber (NBR/EPDM)

- Color

- Black

- Part Type

- Hydraulic Hose

- Product Type

- Wire Braid Hydraulic Hose

- Feature

- High flexibility, leak-proof, abrasion resistant, weather resistant

- Hardness

- 70-90 Shore A

- Components

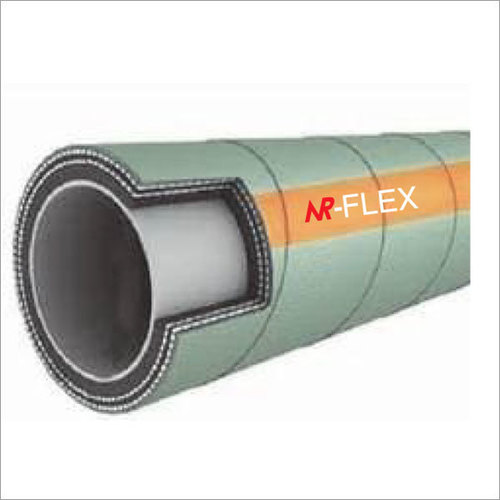

- Inner tube, wire braid reinforcement, outer cover

- Resistance level

- High Pressure, Corrosion & Abrasion Resistant

- Temperature Resistance

- -40C to +100C (up to 125C briefly)

- Weight

- Varies with size (approx. 0.2 - 6.5 kg/m)

- Tolerance

- 0.5 mm

- Material

- Synthetic Rubber and High Tensile Steel Wire

- Diameter

- 6.4 mm to 50.8 mm (Internal Diameter)

- Thickness

- 3.2 mm to 5 mm (Approx.)

- Thermal Conductivity

- Low

- Density

- 1.35 Gram per cubic centimeter(g/cm3)

- Usage & Applications

- Hydraulic systems, industrial machinery, construction equipment, mining

- Surface Finish

- Smooth, Black

- Width

- As per standard or customization

- Natural Rubber

- Blended with synthetic rubber

- Length

- Up to 100 meters (customized lengths available)

- Water Absorption

- Negligible

- Electrical Conductivity

- Antistatic (On Request)

- Ozone Resistance

- Yes, as per ISO 7326

- Cover Type

- Oil & Weather Resistant Synthetic Rubber

- Minimum Bend Radius

- Up to 100 mm (Depending on hose size)

- Packaging

- Coils, pallets, or as per customer requirement

- Inner Tube Material

- Oil Resistant Synthetic Rubber

- Burst Pressure

- 4x Working Pressure

- Reinforcement Type

- Single or Double High Tensile Steel Wire Braid

- Marking

- Continuous identification marking along the hose length

- Working Pressure

- Up to 445 bar (Depending on size and type)

Wire Braid Hydraulic Hose Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

About Wire Braid Hydraulic Hose

Wire Braid Hydraulic Hose

CONSTRUCTION: This hose consists of an inner tube of oil synthetic rubber, single wire braid reinforcement, and an oil and weather resistant synthetic rubber cover

APPLICATIONS: Hose range suitable to carry hydraulic fluids such as glycol, mineral oils fuels, lubrication, emulsion, hydrocarbons etc.

WORKING TEMPERATURE: From -40°C up to+ 125°C

Specification

| Hose ID | Wire OD | Hose OD | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | |||

| Inch | mm | mm | mm | BAR | Psi | BAR | Psi | mm | Kg/m |

| 3/4 | 19.0 | 28.4 | 32.1 | 350 | 5000 | 1380 | 20000 | 240 | 1.68 |

| 1 | 25.4 | 35.2 | 38.7 | 350 | 5000 | 1380 | 20000 | 300 | 2.24 |

| 1-1/4 | 31.8 | 41.9 | 50.2 | 350 | 5000 | 1380 | 20000 | 420 | 3.90 |

| 1-1/2 | 38.1 | 48.8 | 57.7 | 350 | 5000 | 1380 | 20000 | 500 | 5.07 |

| 2 | 50.8 | 63.2 | 71.5 | 350 | 5000 | 1380 | 20000 | 630 | 7.91 |

Superior Performance and Safety

Built with high tensile steel wire braid reinforcement, our hoses surpass industry safety standards by delivering burst pressures up to four times their rated working pressure. The robust design ensures leak-proof operation and durability, even in high-pressure applications, increasing both safety and productivity in hydraulic and industrial machinery.

Versatile Applications and Customization

Wire Braid Hydraulic Hoses are widely used across hydraulic systems, industrial machinery, construction equipment, and mining operations. Available in sizes ranging from 1/4 inch to 2 inches, and customizable lengths up to 100 meters, these hoses offer the flexibility to fit a wide variety of requirements. Packaging and identification marking are tailored to meet client needs.

Durable Construction and Environmental Resistance

The oil and weather-resistant synthetic rubber cover, combined with an oil-resistant inner tube, ensures longevity even in harsh environments. Meeting ISO standards for ozone and flame resistance, and featuring abrasion and corrosion-resistant materials, these hoses maintain integrity and performance under demanding conditions.

FAQs of Wire Braid Hydraulic Hose:

Q: How is the Wire Braid Hydraulic Hose constructed for durability and high pressure?

A: This hose features a robust inner tube made of oil-resistant synthetic rubber, reinforced by single or double layers of high tensile steel wire braid. The exterior synthetic rubber cover provides resistance against oil, weather, abrasion, and ozone. This sophisticated construction enables the hose to withstand working pressures up to 445 bar and burst pressures four times higher, making it suitable for high-pressure hydraulic systems.Q: What are the main uses and industries for Wire Braid Hydraulic Hoses?

A: These hoses are primarily used in hydraulic systems, industrial machinery, construction equipment, and mining operations. Their high flexibility, leak-proof design, and resistance to abrasion make them ideal for situations demanding both high performance and reliability in fluid power transmission.Q: When should I choose single versus double wire braid reinforcement?

A: Single wire braid hoses are typically used for lower pressure applications, while double wire braid reinforcement is recommended for higher pressure requirements where enhanced durability and greater burst strength are desired. Selection depends on the specific working pressure and application needs.Q: Where can these hydraulic hoses be installed, and what customization options are available?

A: Wire Braid Hydraulic Hoses can be installed in any hydraulic or fluid transfer system where extreme pressure, flexibility, and environmental resistance are necessary. They are available in multiple sizes, lengths (up to 100 meters), and packaging formats including coils and pallets, with further options for customized identification marking and electrical antistatic properties upon request.Q: What is the process for ensuring hose quality and compliance with ISO standards?

A: These hoses are manufactured using high quality synthetic rubber (NBR/EPDM) and steel wire, conforming to ISO standards for ozone resistance (ISO 7326) and flame resistance (ISO 8030). Each hose undergoes rigorous testing for burst pressure, durability, and resistance to corrosion and abrasion, ensuring reliable performance and safety in challenging environments.Q: How does the hoses cover material contribute to its weather and corrosion resistance?

A: The outer cover is made from oil and weather-resistant synthetic rubber, which protects against environmental factors like ozone, UV exposure, and harsh weather conditions. This material, along with blended natural and synthetic rubber composition, ensures long-lasting resistance to corrosion and abrasion even in demanding outdoor or industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Hose Category

Carbon Free Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : 120130 kg/cm (average)

Size : Available from 12 mm to 100 mm inner diameter

Style : Wire Braided and Fabric Braided

Part Type : Hose/Pipe

Product Type : Carbon Free Hose

Rubber Air Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : Minimum 10 MPa (varies by manufacturer/spec)

Size : 1/4 inch, 3/8 inch, 1/2 inch, or as specified

Style : Smooth finish with reinforced design

Part Type : Air Hose

Product Type : Rubber Air Hose

Wire Braid Hydraulic Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : High tensile strength (as per EN 853/SAE 100 R1/R2 specs)

Size : 1/4 inch to 2 inch (varies as per requirement)

Style : Reinforced with hightensile steel wire braid

Part Type : Hydraulic Hose

Product Type : Wire Braid Hydraulic Hose

Air - Rock Drill Rubber Hose

Minimum Order Quantity : 50 Meters

Tensile Strength : 15 to 25 MPa

Size : 1/2 inch to 2 inch (nominal bore sizes).

Style : Heavy Duty, Plain, Corrugated

Part Type : Industrial Hose

Product Type : Rubber Hose

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry