Wire Braid Hydraulic Hose

Wire Braid Hydraulic Hose Specification

- Temperature Resistance

- -40C to +100C (continuous); up to 125C (intermittent use)

- Part Type

- Hydraulic hose

- Hardness

- 705 Shore A

- Usage & Applications

- High-pressure hydraulic systems, industrial machinery, construction equipment

- Water Absorption

- Minimal

- Components

- Inner tube, wire braid reinforcement, outer rubber cover

- Tolerance

- ISO 1307 standard

- Resistance level

- Excellent resistance to oil, abrasion, and weather

- Tensile Strength

- Between 180-330 MPa (depending on grade)

- Surface Finish

- Smooth, wear-resistant

- Style

- Reinforced, Braided

- Diameter

- 6.4 mm to 51 mm (ID range)

- Flame Resistance Level

- Meets SAE and ISO flame resistance standards

- Size

- 1/4 inch to 2 inch (ID)

- Width

- Standard widths available upon request

- Material

- Synthetic rubber with high tensile steel wire braid reinforcement

- Rubber Type

- Synthetic rubber (NBR, SBR blends)

- Natural Rubber

- Blended synthetic and natural rubber layer

- Feature

- High pressure resistance, Flexibility, Long service life

- Length

- Standard lengths up to 100 meters

- Thickness

- Varies by size; typically 3 mm to 10 mm

- Product Type

- Wire Braid Hydraulic Hose

- Thermal Conductivity

- Low

- Color

- Black

- Density

- 1.6 Gram per cubic centimeter(g/cm3)

- Weight

- Varies according to size

- Burst Pressure

- Up to 4 times working pressure (varies by model and size)

- Fitting Compatibility

- Compatible with standard hydraulic fittings (crimped or swaged)

- Outer Cover Properties

- Resistant to petroleum oils, abrasion, ozone, and aging

- Conformance Standards

- Complies with SAE 100 R1AT/R2AT, EN 853 1SN/2SN, DIN EN 857 1SC/2SC

- Minimum Bend Radius

- Specified as per size and model, e.g., 100mm for 1/2" hose

- Reinforcement Type

- Single or double high-tensile steel wire braid

Wire Braid Hydraulic Hose Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

About Wire Braid Hydraulic Hose

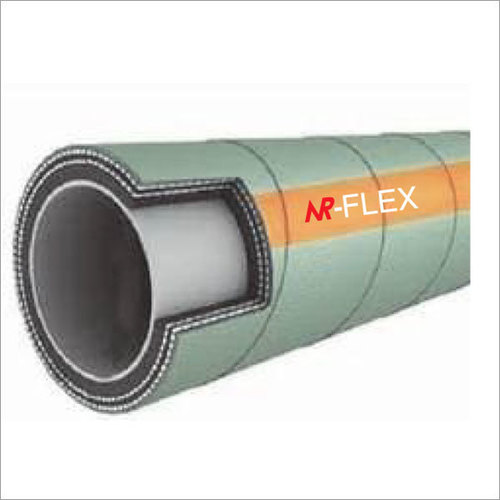

Wire Braid Hydraulic Hose

CONSTRUCTION: This hose consists of an inner tube of oil synthetic rubber, single wire braid reinforcement, and an oil and weather resistant synthetic rubber cover

APPLICATIONS: Hose range suitable to carry hydraulic fluids such as glycol, mineral oils fuels, lubrication, emulsion, hydrocarbons etc.

WORKING TEMPERATURE: From -40°C up to+ 121°C

Specification

| Hose ID | Wire OD | Hose OD | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | |||

| Inch | mm | mm | mm | BAR | Psi | BAR | Psi | mm | Kg/m |

| 1/2 | 12.7 | 20.2 | 24 | 415 | 6090 | 166 | 24000 | 230 | 0.85 |

| 5/8 | 15.9 | 23.8 | 28.2 | 350 | 5075 | 140 | 20000 | 250 | 1.11 |

| 3/4 | 19.0 | 28.4 | 32 | 120 | 3092 | 168 | 24000 | 280 | 1.61 |

| 1 | 25.4 | 35.2 | 38.6 | 380 | 5500 | 152 | 22000 | 340 | 2.00 |

| 1-1/4 | 31.8 | 41.9 | 45.8 | 325 | 4700 | 130 | 18800 | 460 | 2.46 |

| 1-1/2 | 38.1 | 48.8 | 53.3 | 290 | 4200 | 116 | 16800 | 560 | 3.35 |

| 2 | 50.8 | 63.2 | 68.1 | 250 | 3600 | 100 | 14400 | 700 | 4.98 |

Heavy-Duty Steel Wire Braid Reinforcement

Each hose features either a single or double layer of high-tensile steel wire braid, ensuring superior strength and reliability in high-pressure hydraulic systems. This design provides durability and minimizes the risk of hose failure under rigorous use. The reinforcement adheres to both international and industry conformance standards, guaranteeing dependable performance where it matters most.

Exceptional Resistance and Longevity

The outer cover of the hose, made from a blend of synthetic and natural rubber, is engineered for extreme resistance to petroleum oils, abrasion, ozone, and tough weather conditions. This robust construction prolongs hose life, reduces maintenance downtime, and safeguards hydraulic systems in challenging industrial and construction environments.

Flexible Application Across Industries

With sizes ranging from 1/4 inch to 2 inches, these hoses are compatible with standard hydraulic fittings and suitable for a wide array of applications, from industrial machinery to construction equipment. Standard widths and lengths up to 100 meters make them adaptable for diverse requirements, while their minimal water absorption and low thermal conductivity ensure operational reliability.

FAQs of Wire Braid Hydraulic Hose:

Q: How does the wire braid reinforcement enhance the performance of the hydraulic hose?

A: The single or double high-tensile steel wire braid reinforcement significantly boosts the hoses strength and pressure handling capacity, making it suitable for high-pressure hydraulic systems. This reinforcement typology helps prevent hose expansion under pressure and extends its service life in demanding environments.Q: What standards do these hydraulic hoses comply with?

A: Wire Braid Hydraulic Hoses meet stringent standards including SAE 100 R1AT/R2AT, EN 853 1SN/2SN, DIN EN 857 1SC/2SC, and conform to ISO 1307 tolerances. This ensures reliable performance, safety, and interchangeability in global hydraulic applications.Q: When should I choose a hose with a double wire braid over a single braid?

A: Double wire braid hoses are recommended for applications requiring higher working pressures and more robust durability compared to single braid variants. They are ideal for heavy-duty hydraulic machinery and situations with pulsating or shock pressure conditions.Q: Where can these hoses be installed or used?

A: These hoses are well-suited for installation in a variety of locations, including industrial hydraulic systems, construction equipment, agricultural machinery, and other high-pressure fluid transfer systems that demand strength, flexibility, and reliability.Q: What process is involved in connecting these hoses to fittings?

A: The hoses are designed for compatibility with standard hydraulic fittings, which can be attached using crimping or swaging processes. This ensures a secure, leak-resistant connection essential for maintaining hydraulic system integrity.Q: How does the outer rubber cover benefit the hoses lifespan and safety?

A: The outer cover, made from a blend of synthetic and natural rubber, provides excellent resistance to petroleum oils, abrasion, ozone exposure, and adverse weather. This not only extends the hoses lifespan but also enhances safety by preventing premature wear and potential hose failure.Q: What advantages do these hoses offer to users in terms of installation and performance?

A: Users benefit from the hoses flexible design, high-pressure resistance, and adherence to global standards, which simplify installation and ensure reliable operation in harsh conditions. The availability in a wide range of sizes and standard lengths further adds to their versatility and ease of use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Hose Category

Carbon Free Hose

Minimum Order Quantity : 50 Meters

Components : Inner tube, reinforcement layer, outer cover

Part Type : Hose/Pipe

Temperature Resistance : 40C to +180C

Hardness : 70 5 Shore A

Water Absorption : Negligible

Rubber Air Hose

Minimum Order Quantity : 50 Meters

Components : Rubber hose with textile/nylon wire reinforcement

Part Type : Air Hose

Temperature Resistance : 30C to +70C

Hardness : 6070 Shore A

Water Absorption : Low

Sand Blast Rubber Hose

Minimum Order Quantity : 50 Meters

Components : Inner tube, reinforcement (fabric/wire), outer cover

Part Type : Industrial Hose

Temperature Resistance : 40C to +70C

Hardness : 655 Shore A

Water Absorption : Negligible

Water Rubber Hose

Minimum Order Quantity : 50 Meters

Components : Rubber tube, reinforced layer, cover

Part Type : Hose Pipe

Temperature Resistance : 20C to +70C

Hardness : 655 Shore A

Water Absorption : Negligible

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry