Rubber Mat

Rubber Mat Specification

- Resistance level

- Good resistance to abrasion and mild chemicals

- Water Absorption

- Low

- Product Type

- Rubber Mat

- Surface Finish

- Smooth, Textured, Ribbed

- Size

- Customizable, standard roll sizes available

- Thickness

- 3 mm, 5 mm, 10 mm (standard); customizable

- Thermal Conductivity

- Low

- Length

- 10 m (approx. for roll type); customizable

- Nitrogen Content (%)

- Below 1%

- Compression Ratio

- Medium to High compressibility

- Volatile Matter (%)

- Below 1%

- Color

- Black

- Part Type

- Mat

Rubber Mat Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- PVC Polythene Bags

- Main Domestic Market

- All India

About Rubber Mat

With the experience of more than 30 years, we are engaged in manufacturing, exporting and supplying optimum quality Rubber Mat. This mat is widely used in electrical panel room, server room, mcb room, electrical department and various places where electrical risk can occurs. Offered product is precisely manufactured under the guidance of our deft professionals using high quality rubber in adherence with latest machinery. Furthermore, the quality of this product is checked as per set quality standards to ensure the flawlessness at clients' end. Clients can avail this Rubber Mat from us at leading industry price.

Features:

-

Durable

-

High strength

-

Resistance to heat

-

Perfect finish

Versatile Design for Varied Applications

The Rubber Mats customizable dimensions and multiple surface finishes (smooth, textured, ribbed) make it suitable for a wide range of settings, from industrial workshops to commercial spaces. Its medium to high compressibility ensures adaptability to different surfaces and requirements, providing optimal coverage and protection.

Durability Meets Safety

With a low water absorption rate and good resistance to both abrasion and mild chemicals, the mat is built to last and minimize maintenance. The low nitrogen and volatile matter content further ensure a safe working environment, making it an ideal flooring solution for demanding spaces.

FAQs of Rubber Mat:

Q: How can I order a rubber mat with custom size and thickness?

A: You can request a custom size and thickness for the rubber mat by specifying your requirements when placing your order with the distributor. Standard thickness options are 3 mm, 5 mm, and 10 mm, but both length and thickness are customizable to meet your specific needs.Q: What are the key benefits of using this rubber mat in industrial and commercial environments?

A: The mat offers good resistance to abrasion and mild chemicals, low water absorption, and low thermal conductivity. These characteristics enhance safety, reduce wear and tear, and provide reliable insulation, making it highly suitable for demanding environments.Q: Where can these rubber mats be used effectively?

A: These mats are ideal for industrial workshops, commercial facilities, manufacturing floors, and high-traffic areas requiring surface protection, slip-resistance, and chemical resistance. Their versatility makes them suitable for a broad range of applications.Q: What is the manufacturing process for these rubber mats?

A: These mats are manufactured using high-quality rubber, ensuring a nitrogen content below 1% and volatile matter below 1%. This process produces robust material with medium to high compressibility and offers customizable surface finishes for specialized application needs.Q: When is the right time to replace a rubber mat?

A: You should consider replacing your rubber mat when there are visible signs of significant wear, such as thinning, cracking, or when its resistance to abrasion has diminished to ensure continued safety and effectiveness.Q: How should I maintain and clean the rubber mat?

A: The mats low water absorption allows for easy cleaning using a damp cloth or mild detergent. Regular maintenance prevents build-up of debris and preserves the surface finish, whether it is smooth, textured, or ribbed.Q: What usage and benefits does the low nitrogen and volatile matter content provide?

A: Low nitrogen and volatile matter content contribute to enhanced stability, improved fire safety, and a reduced likelihood of releasing harmful emissions, making the mats safer and longer-lasting in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Sheets Category

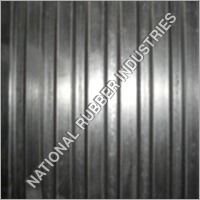

Wide Ribbed Rubber Sheet

Minimum Order Quantity : 50 Meters

Tolerance : 5%

Size : Custom sizes available

Nitrogen Content (%) : 0.5%

Volatile Matter (%) : 1%

Width : 1.2 Meter

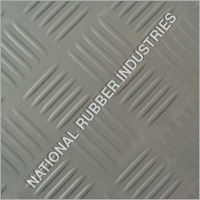

Checkered Rubber Sheet

Minimum Order Quantity : 50 Meters

Tolerance : 5%

Size : Rolls or customized sheets (standard: 10m x 1m)

Nitrogen Content (%) : < 0.3%

Volatile Matter (%) : < 2%

Width : 1000 mm, 1200 mm, or customized

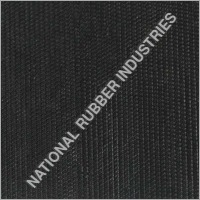

Flat Rubber Sheet

Minimum Order Quantity : 50 Meters

Tolerance : 0.3 mm

Size : Standard & customized sizes available

Nitrogen Content (%) : 0.6%

Volatile Matter (%) : 2%

Width : 1 meter (customizable)

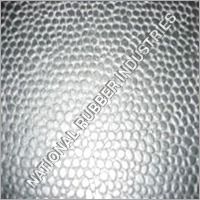

Horse Rubber Sheet

Minimum Order Quantity : 50 Meters

Tolerance : 2 mm

Size : Custom sizes available

Nitrogen Content (%) : 0.7%

Volatile Matter (%) : 2%

Width : 1 m to 1.5 m (approx.)

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry