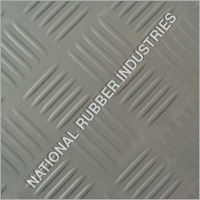

Checkered Rubber Sheet

Checkered Rubber Sheet Specification

- Components

- Rubber compound, fillers, processing aids

- Flame Resistance Level

- Standard (flame retardant grades available on request)

- Volatile Matter (%)

- < 2%

- Tensile Strength

- 3 to 10 MPa

- Density

- 0.05 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- Low (typical for rubber)

- Nitrogen Content (%)

- < 0.3%

- Width

- 1000 mm, 1200 mm, or customized

- Length

- 10 m standard roll (custom lengths available)

- Surface Finish

- Checkered textured

- Tolerance

- 5%

- Size

- Rolls or customized sheets (standard: 10m x 1m)

- Rubber Type

- NR/SBR/Blend

- Water Absorption

- <1%

- Natural Rubber

- Available or blend with synthetic rubber

- Product Type

- Checkered Rubber Sheet

- Compression Ratio

- Good compressibility, ~20%

- Resistance level

- Excellent abrasion and slip resistance

- Ash %

- < 1%

- Part Type

- Sheet

- Weight

- Dependent on size and thickness

- Hardness

- 65 5 Shore A

- Thickness

- 3 mm to 15 mm

- Color

- Black, can be customized

Checkered Rubber Sheet Trade Information

- Minimum Order Quantity

- 50 Meters

- Supply Ability

- Meter

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- All India

About Checkered Rubber Sheet

With the help of our professionals, we have been able to manufacture, export and supply high quality Checkered Rubber Sheet. This is widely used in various industries as it is manufactured by our skilled professionals with advanced machines using high quality rubber. Offered sheet is stringently tested on various parameters to ensure the flawlessness at clients' end. Available in various widths, lengths & thicknesses, this Checkered Rubber Sheet can also be customized as per the requirements of clients.

Features:

-

Tolerant to high temperature

-

Resistance to chemicals

-

Smooth finish

-

Impact resistance

Versatile Rubber Sheets for Industrial Demands

Checkered Rubber Sheets offer an ideal surface for demanding industrial and commercial environments, thanks to their excellent abrasion and slip resistance. Engineered using NR, SBR, or blended rubber, these sheets ensure both safety and longevity for varied applications, from workshop flooring to equipment linings. Their textured surface enhances grip, stability, and impact absorption.

Custom Sizing and Superior Quality

These rubber sheets are available in standard widths of 1000 mm or 1200 mm, with fully customizable sizes on request. Thickness can be tailored from 3 mm up to 15 mm, and custom lengths are available beyond the standard 10-meter roll. With strict tolerance and superior compound formulation, you receive consistent quality and reliable performance every time.

Built for Safety and Durability

Enhanced with a checkered finish, these sheets deliver remarkable compressibility and minimal water absorption (<1%), ensuring enhanced protection on wet or oily surfaces. The rubber compound is flame-resistant up to standard levels, with flame-retardant grades available for higher protection. The low ash and volatile content further ensure longevity and resilience under pressure.

FAQs of Checkered Rubber Sheet:

Q: How can Checkered Rubber Sheets be customized for my project?

A: You can customize checkered rubber sheets in width, length, thickness, color, and overall dimensions. Standard options include 1000 mm or 1200 mm wide rolls, 10-meter standard length, and thicknesses between 3 mm and 15 mm, but bespoke sizes and colors are available upon request.Q: What industries typically use this type of rubber sheet?

A: Checkered Rubber Sheets are widely used in manufacturing, automotive, warehousing, construction, and public transport sectors due to their anti-slip, abrasion-resistant properties and tough, resilient structure. Theyre ideal for flooring, walkways, stair treads, equipment linings, and protective coverings.Q: When is it recommended to use a flame-retardant grade?

A: A flame-retardant grade of checkered rubber sheet is recommended in environments with higher fire-risk potential, such as public buildings, transportation, or industrial facilities where additional safety regulations must be met. Flame-retardant grades are available upon special request.Q: Where can I source these sheets from or have them delivered?

A: As distributors, exporters, manufacturers, and suppliers based in India, we can deliver checkered rubber sheets domestically and internationally, according to client specifications. Contact us to discuss your requirements and delivery options.Q: What is the process for manufacturing Checkered Rubber Sheets?

A: The sheets are produced by mixing natural and synthetic rubber with fillers and processing aids, calendaring into sheets, embossing the checkered pattern for enhanced grip, and curing under controlled conditions to achieve targeted mechanical properties and surface texture.Q: How do these sheets benefit industrial facilities?

A: Checkered Rubber Sheets significantly improve workplace safety by minimizing slip hazards, providing cushioning, absorbing impact, and protecting both personnel and equipment from wear and tear. Their longevity and customizable design add further value and cost-efficiency.Q: What is the recommended method for installing these sheets?

A: These sheets can be laid loose, bonded with adhesive, or mechanically fastened, depending on the substrate and application environment. Ensure the surface is clean and level prior to installation for optimal adhesion and lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Sheets Category

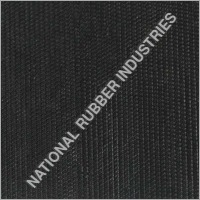

Flat Rubber Sheet

Minimum Order Quantity : 50 Meters

Size : Standard & customized sizes available

Length : 10 meters (standard roll length, customizable)

Compression Ratio : Good compression set (< 35%)

Color : Black

Part Type : Sheet

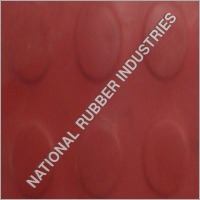

Round Button Rubber Sheet

Minimum Order Quantity : 50 Meters

Size : Standard or as per requirement

Length : 10 meter (roll length) or as required

Compression Ratio : Moderate

Color : Black

Part Type : Sheet

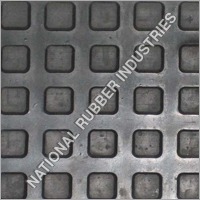

Square Anti-slip Rubber Mat

Minimum Order Quantity : 50 Meters

Size : Standard size 1m x 1m, custom sizes available.

Length : 1 meter typically (customizable)

Compression Ratio : Good compression set 25%

Color : Black

Part Type : Mat/Sheet

Rubber Mat

Minimum Order Quantity : 50 Meters

Size : Customizable, standard roll sizes available

Length : 10 m (approx. for roll type); customizable

Compression Ratio : Medium to High compressibility

Color : Black

Part Type : Mat

|

NATIONAL RUBBER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry